The production of iron began years ago in south west or south central Asia. When the Iron Age began, it started replacing bronze in equipments and weapons. Iron replaced bronze because iron is harder, stronger and holds a sharper edge. Iron was then replaced by Steel but Iron has been the material basis of human civilization in Africa, Asia and Europe. Iron is the most available element that covers five per cent of the earth’s crust.

Steel in world’s economy

There are more than two million people working directly in the steel industries across the worlds. Approximately two million contractors and four million people are working in supporting industries. This makes steel a key driver in world’s economy. Steel is a key product in almost all fields like automotive, construction, power, and transport, machine goods and many more. Companies delivering renewable energy like solar, wind and tidal is also dependent on the industry of steel. In 40 years, many countries have entered the top producers of steel. India, Brazil, South Korea, Turkey are few among the top countries that produces steel. Steel can be recycled and used again; 150 year old steel can be recycled to be used for creating new products and applications. In the past 30 years, the energy required in the production of steel has been reduced by 50 per cent. The main authority of steel for its development of iron and steel industry is Ministry of steel. There is a dedicated committee appointed by the Government to monitor the price fluctuations and the behaviour of steel market.

Steel is used everywhere and in every aspect

Due to their strength, versatility and form steel is used in our day to day life in all that we use. Safety equipments, surgical items and even kitchens are made of steel. Steel is hygienic and easy to clean. Steel food cans are also produced to store food. Building, skyscrapers and other construction industries also use steel. Steel is one of the major industries in India. Though it’s providing many employment opportunities, there are few draw backs. Due to the increase in the Indian population, the steel industry is not having enough land available to support the volume of production. Due to the growth of steel industry, domestic and foreign investors are ready to invest for the steel companies.

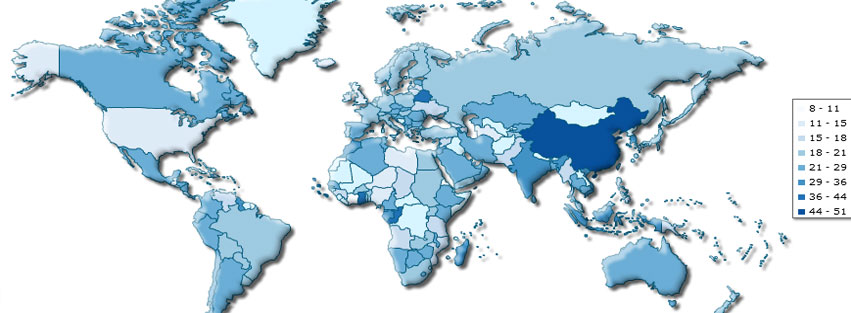

China is the world’s largest steel producer, Japan falls as the second followed by United States as the third producer and India is in the fourth position in the steel industry. The global integration of the economy as well as the rise in the demand by infrastructure, real estate, automobile and other industries makes industry of steel a fast growing one. The industry is also going to provide employment to more and more people. Government is also going to lend its hand for the economic growth and development of steel. The industry is getting healthier and stronger. The industry need to focus on the technology and operations to excel and produce efficiently.

Recycling and reuse

Making steel cans from recycled material uses 75% less energy than producing them from raw materials. Recycling 1kg of steel keeps 2kg of greenhouse gases out of the atmosphere. Recycling steel diverts these products from landfill, and enables the material to be reprocessed, thereby conserving raw materials. For every tonne of steel recycled 1131 kg of iron ore, 633 kg of coal and 54 kg of limestone are saved.

All types of steel can be recycled including food tins, bottle tops, paint cans, aerosols and scrap metal. By recycling and reuse of steel we can avoids or reduces waste and saves primary resources.

Steel is fully recyclable .the overall average end-of-life recovery rate for steel from buildings has been estimated from surveys to be 96%